Cost of tunnel fire protection panels

Tunnel fire protection panels work as the passive method of safeguarding the tunnel structure from damaging effects of elevated thermal loads.

There are also other methods of fire protection in tunnels.

However, each method has its associated pros and cons.

What is more, different solutions will have different financial implications for the installers and different costs for the tunnel operators.

In this blog post I will present various costs and savings of tunnel fire protection panels.

This article is based on the paper titled Economic feasibility study for the use of fire protection panels in road tunnels.

Fires with high Heat Release Rate (HRR) can cause significant damage to the tunnel structure.

Based on the past experiences, we know it may often lead to lengthy closures for refurbishment, sometimes lasting several months. These closures can have a considerable negative impact, as tunnels typically play a crucial role in the surrounding transportation network.

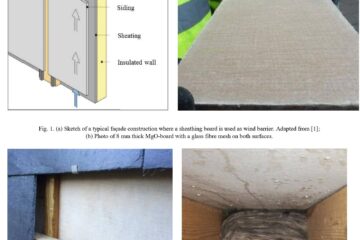

Consequently, diverted traffic may cause blockades and access to certain areas or entire regions may be limited. To mitigate the effects of fire incidents, tunnel fire protection boards are currently being installed on the inner surfaces of tunnels to shield them from extreme heat.

The study, which authors are Roland Leucker, Bernd Gielnik and Christian von STIEGLITZ, presented here not only highlights the investment and ongoing costs associated with fire protection boards but also emphasizes the benefits they provide. For a specific tunnel, it is demonstrated that using fire protection boards can be a cost-effective alternative.

Tunnel fire statistics

The paper quoted above used data which was available at the time – meaning fire statistics from 2006 to 2012 published by the Austrian highway operator ASFINAG.

The data revealed that Austrian highway and expressway tunnels experienced an average of 6.5 fires for every 1 billion vehicle kilometres travelled in tunnels.

The likelihood of truck fires (vehicles ≥ 3.5 tons) is notably higher, with 25 fires per billion tunnel kilometres travelled, compared to 4.2 fires for passenger cars.

Statistically, this means that for every 40 million kilometres travelled in a tunnel, a truck fire is expected to occur.

If you check the raw data from ASFINAG, prepared by ILF Consulting Engineers, you can see that there were 67 fires in Austria from May 2006 to December 2012. That gives approx. 10 fires per year on average.

Another publication by International Fire Academy about Tunnel fires from 2012 to 2023 – International Fire Academy analyses media reports shows that from 2012 until 2023 there were 93 road tunnel fires in Austria during 12 years. Which gives 7.75 fires per year. Just bear in mind that this second data source only relies on the media reported fires.

If you want to reach to other sets of data you can refer also to the statistics about tunnel fires in China Study on Fire Accidents in Tunnels – China.

Moreover, there’s also the publication by CETU which presents tunnel fire statistics from 96 French tunnels between 2002 and 2011.

You can find the same document also here:

CETU-breakdowns-accidents-and-fires-in-road-tunnels-statistics-France.pdf

Why tunnels need fire protection panels

Fire protection boards are mainly used in tunnels to shield the structural concrete from heat damage.

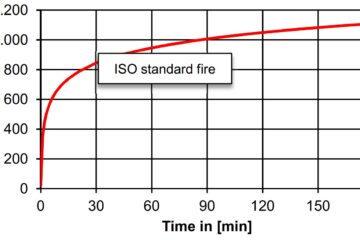

When concrete is subjected to intense heat, particularly when temperatures rapidly rise above 300 °C water evaporation occurs within it.

This leads to high vapor pressure forming just a few centimetres beneath the concrete’s surface, often causing the concrete to spall.

As a result, the reinforcing steel becomes exposed to high temperatures and progressively loses its strength, especially above 300°C.

Fire protection boards are designed to keep both the surface temperature of the concrete and the temperature of the reinforcing steel below critical levels during a fire. These boards can withstand extreme temperatures, typically up to at least 1350 °C. What is more, they greatly reduce the rapid transfer of heat into the concrete, thereby preventing damage.

Consequently, after a fire, only the affected tunnel fire protection panels need to be replaced, with no need for concrete repairs.

Regarding the service life of fire protection boards, the European Technical Approval ETA-17/0170, for example, specifies a minimum lifespan of 25 years for a commercial-grade fire protection board.

However, it is likely that, similar to (light) concrete, these boards will have much longer lifespans.

In this context, the 30-year service life claimed by the manufacturer seems realistic.

In special cases, after reviewing the design and project requirements the service life can be extended beyond 30 years. Nevertheless, for the sake of the study the authors used this number as their basis for calculations.

Life Cycle Cost Analysis Model for tunnel fire protection panels

When planning construction projects, it’s important to consider both initial costs and long-term expenses. Tunnels have long lifespans, so future costs like operation, maintenance, and repairs should be factored in. The DAUB (German Tunnelling Committee) recommends using a life cycle cost analysis. This approach considers not just the construction costs but also the replacement of parts over time, using an interest rate to adjust future costs.

The study refers to the data regarding interest rates and inflation from 2016 to 2019. This is due to publishing the study in 2020. We all know that interest rates changed since that time.

Over long periods, like the 100 years, inflation impacts prices. However, inflation is not considered in the study. Authors assumed that the prices would change evenly, so inflation doesn’t affect the result. Predicting inflation adds more uncertainty than accuracy, so the authors used the “actual value approach” instead.

The model also accounts for the different lifespans of tunnel components. It calculates costs using an annuity factor that includes both interest rates and the component’s lifespan.

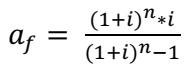

The annuity factor

The varying lifespans of different components are factored into the life cycle cost calculation using the annuity factor (af). This calculation takes into account both the interest rate (i) and the component’s useful life (n) as follows:

Using an interest rate of 1.7% and a 30-year lifespan for fire protection boards, the annuity factor for production and installation is calculated at 0.043.

Maintenance, which occurs every six years, has a higher annuity factor of 0.177.

To find the annual construction costs you can multiply the investment costs of each component by its annuity factor.

The total annual building costs are then multiplied by the present value factor, which is 1 divided by the annuity factor (bf = 1/af).

For example, with an interest rate of 1.7% and a 100-year lifespan, the present value factor is 47.923.

The article authors focused only on the cost-effectiveness of tunnel fire protection boards. They didn’t consider other construction costs in comparing tunnels with and without these fire protection panels.

Maintenance costs for both options are nearly the same. However, you should consider additional expenses for maintaining and repairing the fire protection boards. Especially if they need to be removed and reinstalled for structural inspections.

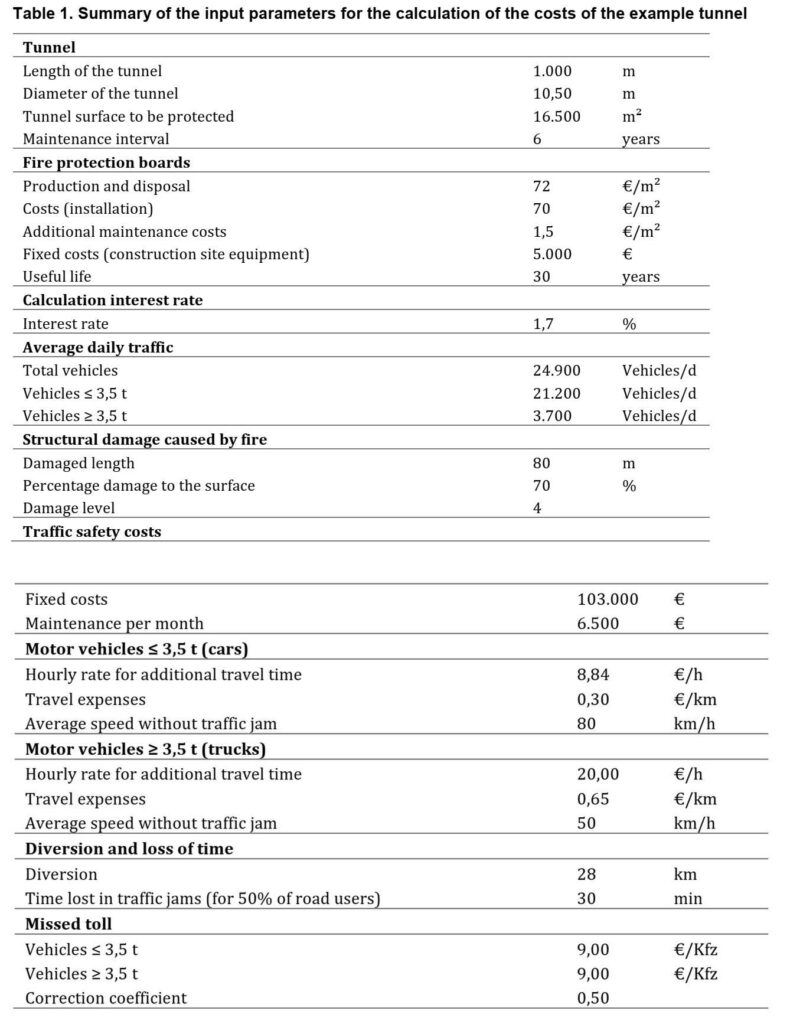

Parameters for calculating costs of tunnel fire protection boards

The authors used the following input parameters for their lifecycle cost calculation:

Tunnel repair costs after the fire event

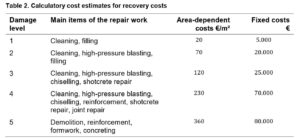

The authors used another publication titled “Protection of critical bridges and tunnels in the course of roads” to assess the damage level. Based on the severity criteria and input data they chose Damage Level 4 for a tunnel without any fire protection boards. This is further defined as spalling in a large area with exposed rebar.

The creators of the study considered the following rehabilitation works when calculating the costs of tunnel repair after the fire event.

The above only mentions actual construction related works. There are numerous other activities that take place to organise the repairs. For example organising a tender for rehabilitation works if this fall out of standard maintenance contracts.

Other actions that need to take place are:

- informing the public about the fire and planned closure works

- investigation of fire event and co-operation with firefighting and emergency services

- preparing relevant documents to local governmental agency

- planning and organising diversion routes

- organising additional personnel from the tunnel operators team to manage and supervise repair works

Last, but not least the authors write about the cost of missed tolls.

Drivers need to pay to drive through many tunnels. In case of tunnel closure for repairs, there is a loss of income for the tunnel operator.

Factors not considered in the study

As the authors righteously point out there are many other factors that are difficult to calculate with monetary values. These are for example:

- increased noise in the diversion areas

- increased damage to the local roads along the diversions

- higher exhaust emissions in the diversion areas

- potentially higher accident rates due to increased traffic

- other costs to the local community and business caused by the closed tunnel (in my understanding these might be delays to meetings, missed travel arrangements, missed business opportunities and extra stress for increased driving time)

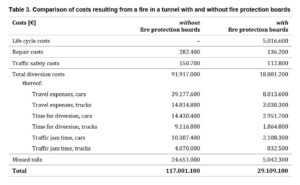

Comparison of costs

The results for the example tunnel show that not installing tunnel fire protection panels is far more expensive than installing them.

In the case of the toll tunnel with just one major fire in 100 years, the toll revenue lost during closure is already four times higher than the life cycle costs of fire protection boards. Additionally, the there are other extra costs influencing the economic comparison.

When all costs are combined, the damage is 15 to 20 times greater than the cost of installing tunnel fire protection panels.

While this result may not apply to every tunnel, the cost of installing fire protection boards is likely to be recovered over the tunnel’s lifetime if there is at least one major fire. Although predicting such fires is impossible, ASFINAG tunnel fire statistics suggest that it is very likely.

What authors don’t mention, but you can read it another quoted publication (here) is the increase in fire accidents. According to the article the potential causes are the increase in road traffic and the growing number of road tunnels.

A risk analysis can help determine the likelihood of a tunnel fire. Factors like tunnel location, length, heavy traffic, and the gradient near the tunnel play a role in this. Fire protection boards are recommended for tunnels with a high risk of vehicle fires or where closure would result in significant economic costs.

This topic is also covered in the tunnel-online.info portal – Consequential Costs and Cost-Effectiveness of Fire Protection Boards Used in Tunnels

and by our partners – Ecotunnelling.

4 Comments

Passive Fire Protection in Tunnels - an introduction · 5 September 2024 at 5:34 pm

[…] You can dive into another post that breaks down the STUVA study on economical aspects of using tunnel fire protection panels. […]

How to select the right fire board for tunnels - Tunnel Passive Fire protection - fire boards and fire cladding · 26 September 2024 at 8:54 am

[…] another post we review the STUVA economical feasibility study on benefits of using tunnel fire protection panels. This article concentrates on the various aspects which tunnel operators need to consider. It […]

터널의 수동식 화재 방호 - 개론 · 10 December 2025 at 12:50 pm

[…] 터널 방화판 사용의 경제적 측면을 분석한 STUVA 연구 보고서를 다른 게시글에서 자세히 살펴보실 수 있습니다. […]

터널에 적합한 방화판을 선택하는 방법 · 10 December 2025 at 1:41 pm

[…] […]