Introduction to Passive Fire Protection in tunnels

Passive fire protection In the realm of fire engineering is a concept which stands as a cornerstone in ensuring the safety and integrity of structures, particularly in environments as challenging as tunnels.

Passive fire protection encompasses a range of measures designed to contain fires, limit their spread, and provide safe egress routes for occupants.

Unlike active fire protection systems, which rely on mechanisms like ventilation, sprinklers and alarms, passive fire protection features elements that are inherently fire-resistant and do not require activation to function effectively.

Tunnel fire protection and fire safety in tunnels

Tunnels present a unique set of challenges in terms of fire safety. The confined spaces, limited ventilation, and potential for rapid smoke spread pose significant risks to both human life and critical infrastructure.

In the event of a fire, the consequences can be catastrophic, with the potential for loss of life, property damage, and disruption to transportation networks. This underscores the importance of robust passive fire protection measures tailored specifically to tunnel environments.

Key components of passive fire protection in tunnels include fire-resistant materials, such as concrete, steel, and specialized fire boards, along with measures for compartmentation and structural integrity. These elements of fire protection systems for tunnels work together to create barriers that contain fire and smoke, preventing them from spreading throughout the tunnel and allowing for safe evacuation routes to be established.

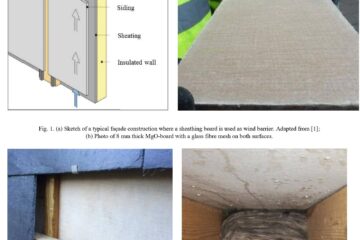

Among these components, fire boards play a crucial role in enhancing tunnel fire safety. These boards are specially designed to withstand high temperatures and provide a barrier against radiation, flames and smoke. Typically made from materials like cementitious compounds, fire boards offer a combination of insulation properties, durability, and ease of installation, making them well-suited for use in tunnel environments.

In the following blog posts, we will delve deeper into the specifics of passive fire protection in tunnels, with a particular emphasis on the role of fire boards. We will explore different types of fire boards, their installation and maintenance requirements, testing and certification standards, as well as real-world case studies highlighting their effectiveness in mitigating fire incidents.

By understanding the principles and applications of tunnel fire protection, we can work towards creating safer and more resilient tunnel infrastructure for the benefit of all.

Why do we need tunnel fire protection?

Tunnel fire protection system acts as a critical line of defence by containing high temperature and protecting the tunnel from structural collapse. This also provides precious time for occupants to evacuate and for emergency services to arrive. The urgency is heightened by the intense heat generated in a tunnel fire.

As investigated from large scale tunnel fires heavy goods vehicles (HGVs) can produce a Heat Release Rate (HRR) exceeding 250 Megawatts (MW), enough to rapidly raise temperatures.

SP Technical Research Institute in Sweden carried out most notable large scale fire test called Runehamar Tunnel Fire Test.

You can watch the summary of this fire test here:

The Runehamar test report investigates parameters such as heat release rate, gas temperature, flame length, radiation, ventilation, and more. The paper also includes theoretical models to predict these parameters. The report can be useful for engineers working on fire safety in tunnels.

This is critical because concrete, a common tunnel lining material, can begin to spall (crack and lose pieces) at around 300-400°C, and melt at even higher temperatures. Concrete spalling and it’s extreme version in the form of explosive spalling poses critical risk for tunnel structures.

Without tunnel fire protection system in place, a tunnel fire could quickly escalate, superheating the concrete and compromising structural integrity. By incorporating fire-resistant materials and compartmentalization strategies, passive fire protection ensures tunnels remain safer during emergencies. What is more, it stays safe after the fire event.

Brief history of fires in tunnels

Mont Blanc Tunnel Fire: A Tragedy Etched in History (1999)

The Mont Blanc Tunnel fire, which ripped through the Alpine passage connecting France and Italy in 1999, stands as a grim reminder of the devastation tunnel fires can cause. A faulty truck brake sparked the inferno, quickly engulfing the vehicle and releasing a peak Heat Release Rate (HRR) estimated to be over 300 Megawatts (MW). The intense heat overwhelmed fire crews and rapidly spread, tragically claiming the lives of 39 people.

This disaster exposed vulnerabilities in tunnel safety protocols and led to stricter regulations and a renewed focus on fire prevention measures.

The following documentary presents detailed information about the catastrophic events of the Mont Blanc Tunnel Fire:

Channel Tunnel Fire: A Near Miss (1996)

While not as catastrophic as the Mont Blanc fire, the 1996 Channel Tunnel blaze serves as a cautionary tale. A fire ignited on a Eurotunnel shuttle train carrying cars and passengers. Thankfully, due to swift emergency response and robust fireproofing within the tunnel, the blaze was contained, and all passengers were evacuated safely. However, the incident highlighted the potential dangers of even smaller fires within tunnels and the importance of effective compartmentalization and ventilation systems. The peak HRR during this fire was estimated to be around 100 MW, significantly lower than the Mont Blanc fire due to the quicker intervention and fire-resistant materials present.

Dr Ricky Carvel presented the lecture about fire dynamics during this fire event:

These both tragic events served as a catalyst for improvements in tunnel safety.

Tunnel Fire Curves

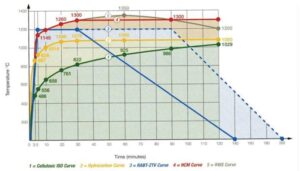

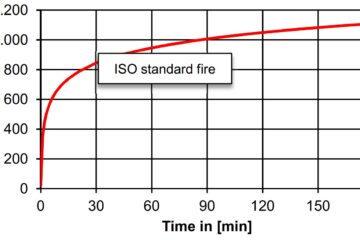

To design effective fire safety measures, engineers rely on fire curves – mathematical models that represent the expected temperature rise over time in a fire scenario.

Tunnel Fire Curves – source: https://tunnelingonline.com/tunnel-design-fire-loads/

The fastest spreading fire in terms of the peak temperature and time is represented by RWS fire curve.

With 1350°C within the first 60 minutes of fire, RWS fire curve is the most severe representation of fire hazard within tunnels.

This design fire curve is based on a assumption of heavy good vehicle like a tanker transporting 50m3 of fuel. It may result in a fire load of 300MW lasting up to 120 minutes.

Runehamar test (mentioned above) confirmed details from the RWS fire curve.

Numerous engineers and designers around the world use RWS fire curve as a reference for specification of requirements of passive fire protection in tunnels.

There’s more information about the design fire curves for tunnels here.

What are the solutions for tunnel fire protection system?

Tunnelling industry recognises three major solutions for passive fire protection in tunnels. Sometimes these are used as individual systems. However, it happens that a combination of more than one of them is applied.

Fire boards

These are also referred as fire protection panels, thermal barrier or thermal cladding – which means engineered and tested boards applied to the tunnel walls and ceilings. For example Aestuver Tx tunnel fire board is a cementitious material tested for severe tunnelling environment.

Installation contractors use tunnel fire protection boards in two ways.

First one, most popular, is a post-fixed system. In this case tunnel structure is competed and installers fix tunnel fire boards with mechanical anchors to concrete walls and ceilings. It works well for rectangular section tunnels and TBM tunnels as well. In case of the round section tunnel, fire boards are faceted to follow the radius of the tunnel.

Aestuver Tx fire board installation – credit Täby BrandskyddsTeknik AB

Source: https://www.tunnel-online.info/en/artikel/tunnel_Cement-based_glass_fibre-reinforced_Tunnel_Fire_Protection_Boards-3076804.html

Second method is to use tunnel fire boards as permanent formwork system or cast in place solution. With this approach, installers place the tunnel fire protection panels onto the tunnel formwork. In most cases they don’t need to use any additional mechanical fixings.

Permanent formwork system is mostly suitable for cut and cover tunnels. It also works great for pre-fabricted tunnel segments in case of an immersed tunnel.

So far the cast-in concrete method of installation cannot be used for the bored tunnels. Nevertheless, contractors apply thermal protection barrier to TBM tunnels using post-fixed method as described above.

This website will focus on numerous aspects of tunnel thermal barrier panels.

How much does it cost to install tunnel fire boards system?

You can dive into another post that breaks down the STUVA study on economical aspects of using tunnel fire protection panels.

This study compares costs for tunnel operators between a tunnel without fire protection boards and a tunnel with them.

Sprayed mortar

Another material which contractors use is a sprayed mortar. Dry mix component is mixed with water and pumped through the machine and sprayed over the tunnel walls. Sprayed system may also require reinforcement mesh and trowelling of surface.

From the experience of our partner installers sprayed fire protection for tunnels is often more difficult to manage and install than tunnel fire boards.

Polypropylene (PP) fibres

Tunnelling contractors may add PP fibres to the concrete mix of tunnel structure. The sizes and amount depends on the mix requirements and performance criteria. In case of fire PP fibres begin to melt in approx. 160-180°C. This also creates micro cracks where water vapour can expand mitigating the pressurising inside the concrete pores. Such process prevents spalling.

Nevertheless, after the fire event the layer with melted PP fibres needs to be removed and repaired. This creates logistical and technical challenges. Tunnel operators may need to shut down the tunnel for several days. Whereas fire boards can be easily replaced in one shift if these are damaged in fire.

Further information about passive fire protection in tunnels

As written in the title of this blog post, this is just merely an introduction to the topic of tunnel fire protection.

You can follow other blog posts on this website to learn more about tunnel fire safety systems and fire protection boards for tunnels.

4 Comments

How to select the right fire board for tunnels - Tunnel Passive Fire protection - fire boards and fire cladding · 17 July 2024 at 5:59 pm

[…] tunnels are an important asset that protects integrity of the structure. Safety is paramount, and passive fire protection in tunnels is a critical consideration. Selecting the right fire protection board for your tunnel project is […]

What are the design fire curves for tunnels? - Tunnel Passive Fire protection - fire boards and fire cladding · 27 August 2024 at 2:08 pm

[…] requirements in tunnel construction. These requirements encompass the design and application of fire-protection cladding, in tunnels as well as the formulation of effective evacuation and rescue strategies in the event of a fire. […]

RWS fire curve - Tunnel Passive Fire protection - fire boards and fire cladding · 19 September 2024 at 11:06 am

[…] tunnel fire test which we referred to in the introduction to passive fire protection in tunnels, confirmed the fire loads and parameters which are applied in the RWS fire […]

ISO curve - ISO 834 time-temperature fire curve · 29 November 2024 at 11:18 am

[…] It’s one of the many time-temperature fire curves which are also used in designing fire protection in tunnels. […]