RWS Fire Curve: A Key Tool for Tunnel Safety and Tunnel Fire Protection

Fire safety in tunnels is a critical aspect of modern infrastructure design, especially when it comes to preparing for extreme fire events. One of the most important tools used to model and mitigate these risks is the RWS fire curve. It was developed by the Dutch Ministry of Infrastructure (Rijkswaterstaat), this curve is specifically designed to simulate the intense and prolonged fires that can occur in road tunnels, particularly those involving tanker trucks carrying large quantities of flammable liquids.

Runehamar tunnel fire test which we referred to in the introduction to passive fire protection in tunnels, confirmed the fire loads and parameters which are applied in the RWS fire curve.

In this article, we’ll explore the RWS fire curve, its significance in tunnel design, and how it compares to other fire curves used in fire safety engineering.

What is the RWS Fire Curve?

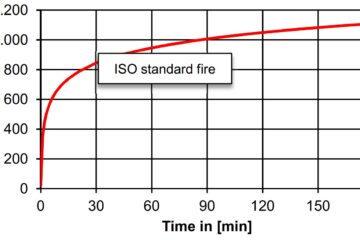

The RWS fire curve is a time-temperature graph that simulates a large-scale fire, such as a tanker truck fire, in a confined environment like a tunnel. It is particularly severe and models the scenario of a fire involving 45,000 litres of gasoline. The fire curve simulates how a fire would behave over time, with a rapid rise in temperature, sustained high heat, and a gradual cooling phase.

Here’s a breakdown of the RWS fire curve’s key characteristics:

Source: https://commons.wikimedia.org/wiki/File:Rws_tunnel_curve.jpg

– Maximum Temperature: The fire temperature reaches a peak of approximately 1350°C (2462°F), which is far higher than typical building fire scenarios.

– Maximum Temperature on the concrete surface – not grater than 380°C

– Maximum Temperature for the reinforcement – not grater than 250°C

– Time Duration: The fire maintains this high temperature for an extended period, often 2 hours. In some cases, modifications to the curve extend the duration of high heat for up to 3 hours.

– Purpose: The curve is used to assess the fire resistance of tunnel structures and materials, ensuring they can withstand intense heat without compromising structural integrity.

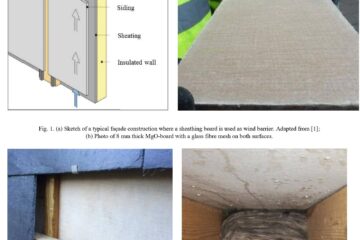

In recent years tunnel designers and operators require to carry out fire test on the concrete specimen which are to be used as tunnel lining. Sometimes it happens that the spalling effect occurs even in temperatures under 380°C. In such cases the tunnel fire protection system has to be able to protect the concrete at these lowered temperatures.

Source: efectis.com

Why Was the RWS Fire Curve Developed?

Tunnels are essential components of modern transportation networks, especially in urban areas and mountainous regions. However, they also pose unique challenges when it comes to fire safety. Fires in tunnels, particularly those involving vehicles carrying flammable materials like gasoline or diesel, can reach extremely high temperatures and last for extended periods, making them more dangerous than typical building fires.

The RWS fire curve was developed to simulate the worst-case fire scenarios in road tunnels, such as a fully engulfed tanker fire. By using this curve in design and safety evaluations, engineers can ensure that tunnels are equipped with sufficient fire protection measures.

Rijkswaterstaat (RWS), the operational branch of the Dutch Ministry of Infrastructure and Water Management, has established stringent fire resistance requirements for road tunnels in the Netherlands. These specifications are largely based on the fire testing procedures outlined in the “2008-Efectis-R0695 Fire testing procedure for concrete tunnel linings.”

The initial testing guidelines were introduced in 1986 with TNO’s report “BI-86-69 – Tunnel Protection Fire Test Procedure,” which included tests on concrete slabs using a newly developed RWS fire curve simulating a hydrocarbon fire. In 1998, RWS and TNO (now Efectis Nederland) co-developed a more comprehensive procedure in the document “1998-CVB-R1161 (rev.1) – Fire Protection for Tunnels,” which expanded on the testing of fire protection systems and included assessments of concrete spalling behaviour during fires.

Efectis released an updated version of this procedure in 2008 as the “2008-Efectis-R0695” document, designed to accommodate a broader range of tunnel designs and fire protection materials. More recently, as fire protection technology has advanced, and new fire-resistant materials have emerged, RWS and Efectis revised the procedure again in 2020. This revision includes new standards for assessing the composition of concrete to better evaluate spalling, as well as fire resistance tests for additional tunnel components like doors and cable ducts. The latest updates also introduced on-site testing capabilities through the use of mobile furnaces, recognizing the growing demand for in-situ fire safety evaluations. En example of such a test is described by one of the contractors for passive fire protection – TBT and also by Efectis.

The 2020 version, titled “Efectis-R0695 2020 Fire testing procedure for concrete tunnel linings and other tunnel components,” incorporates these changes to reflect the most up-to-date knowledge and practices in tunnel fire safety.

How is the RWS Fire Curve Used?

The RWS fire curve is used in tunnel design and construction to evaluate the fire resistance of structural elements, including:

– Concrete Linings – Concrete in tunnels must be able to withstand extreme heat without cracking or spalling, which can compromise the tunnel’s structural integrity.

– Steel Reinforcements – Steel reinforcements within the tunnel must also resist heat, preventing collapse during and after a fire.

– Tunnel Fire Protection Systems – tunnel passive fire protection materials, fire boards or fire-resistant cladding, and ventilation systems are designed based on the temperature and duration of fires modelled by the RWS curve.

By applying the RWS curve, tunnel designers ensure that even in the event of a large-scale fire, the tunnel’s structure will remain intact long enough to allow for safe evacuation and firefighting operations.

Comparison to Other Tunnel Fire Curves

The RWS fire curve is just one of several fire curves used in fire safety engineering, each representing different fire scenarios:

– ISO 834 Curve: The ISO 834 fire curve is a standard fire curve used in general building design. It represents typical fire scenarios in buildings, with a lower maximum temperature (around 1000°C) compared to the RWS curve. While it is suitable for standard buildings, it does not account for the extreme conditions of tunnel fires.

– Hydrocarbon Curve (HC): The hydrocarbon curve is used to simulate fires involving hydrocarbon fuels, such as oil and gas. It reaches a temperature of around 1100°C and is used in industrial settings, offshore platforms, and some tunnel designs. The RWS curve represents a more severe scenario, with a higher peak temperature and longer duration.

– Modified Hydrocarbon Curve (HCM): The HCM curve is an adaptation of the hydrocarbon curve, with a higher peak temperature of around 1300°C. It is also used in tunnels but represents a slightly less intense fire scenario compared to the RWS curve.

Countries and standards that apply RWS fire curve

The RWS fire curve is widely recognized and used in several countries for tunnel fire safety, particularly in the context of road tunnels. Some of the key countries that incorporate the RWS fire curve into their national standards or design practices include:

The Netherlands – As the originator of the RWS fire curve, the Netherlands uses this curve extensively in its national standards for road tunnel design and fire safety.

Belgium – the Dutch speaking regions of Belgium also utilise RWS curve in the tunnel specification and design.

Poland – recent update of construction regulations for tunnels includes RWS fire curve for Polish road tunnels. The full text is here.

USA – NFPA 502 refers to fire protection of tunnels with RWS fire curve.

Saudi Arabia – on numerous projects in Saudi Arabia we came across requirements as per NFPA 502.

South Korea – recent updates by the Korean Ministry of Land, Infrastructure and Transport in Road Tunnel Fireproofing Guidance also mention RWS fire curve

The Importance of Fire Curves in Tunnel Safety

Fire curves like the RWS are essential tools for ensuring that tunnels are designed with the highest safety standards. By simulating real-world fire scenarios, these curves help engineers determine the necessary fire resistance of materials and structures. Tunnels, due to their confined nature, require robust fire protection to prevent catastrophic damage and ensure the safety of occupants during evacuation.

In addition to structural design, fire curves also inform the development of ventilation systems and fire suppression technologies. These systems must be able to manage extreme heat and smoke to protect both the tunnel’s structure and the people inside.

The RWS fire curve is a critical tool in the field of tunnel fire safety, particularly for road tunnels. By simulating the intense conditions of a large-scale fire, such as a tanker fire, the RWS curve ensures that tunnels can withstand extreme heat and continue to provide safe passage for evacuation and firefighting operations.

As infrastructure grows and transportation networks become more complex, the use of advanced fire curves like the RWS will be key to protecting lives and preserving critical structures. Through rigorous testing and adherence to fire safety standards, tunnels can be designed to endure even the most severe fire scenarios, ensuring they remain safe and functional in the event of an emergency.

What is RWS120?

It’s a description of the RWS fire curve that lasts for 120 minutes. Within that time the temperature rises rapidly to 1350°C within first 60 minutes and stays at 1200°C until 120 minute mark.

What is RWS180

It’s an RWS fire curve with duration of 180 minutes. In the first hour of the test the temperature peaks at 1350°C and than drops to 1200°C until 180 minutes of total duration.

Aestuver Tunnel Fire Proofing Boards and the RWS Fire Curve

Why are we even discussing this fire curve in the context of Aestuver tunnel fire protection boards?

One of the best ways to protect tunnel structures from the devastating effects of fire is to use Aestuver fire proofing boards.

By installing Aestuver fire protection you can limit the maximum temperature on the concrete surface to the design requirements.

The Aestuver tunnel board has been tested under RWS fire conditions, i.e., RWS120 and RWS180. The board thickness in these cases is selected based on the design requirements and the maximum allowable temperatures on the concrete surface. In this way, the Aestuver tunnel board protects the structure against fire induced spalling.

4 Comments

What are the design fire curves for tunnels? · 19 September 2024 at 11:06 am

[…] The RWS fire curve is designed to simulate severe fire conditions that road tunnels might experience, especially those […]

Passive Fire Protection in Tunnels - an introduction · 19 September 2024 at 11:07 am

[…] The fastest spreading fire in terms of the peak temperature and time is represented by RWS fire curve. […]

How to select the right fire board for tunnels - Tunnel Passive Fire protection - fire boards and fire cladding · 19 September 2024 at 11:09 am

[…] Fire resistance rating: Local regulations will dictate the required fire resistance time for the boards. This translates to how long the boards must maintain structural integrity under extreme heat. Different countries specify different requirements. The most popular fire curve applied for tunnels fire protection is RWS fire curve. […]

Fire safety in tunnels - Tunnel Passive Fire protection - fire boards and fire cladding · 13 November 2025 at 8:53 am

[…] ordinary loads can generate fires comparable to oil tankers, with temperatures exceeding 1300°C. The RWS curve, developed in Holland, represents the most severe fire scenario and is widely used for testing […]