Why Magnesium Oxide Boards (MgO boards) Are Not Suitable for Tunnels

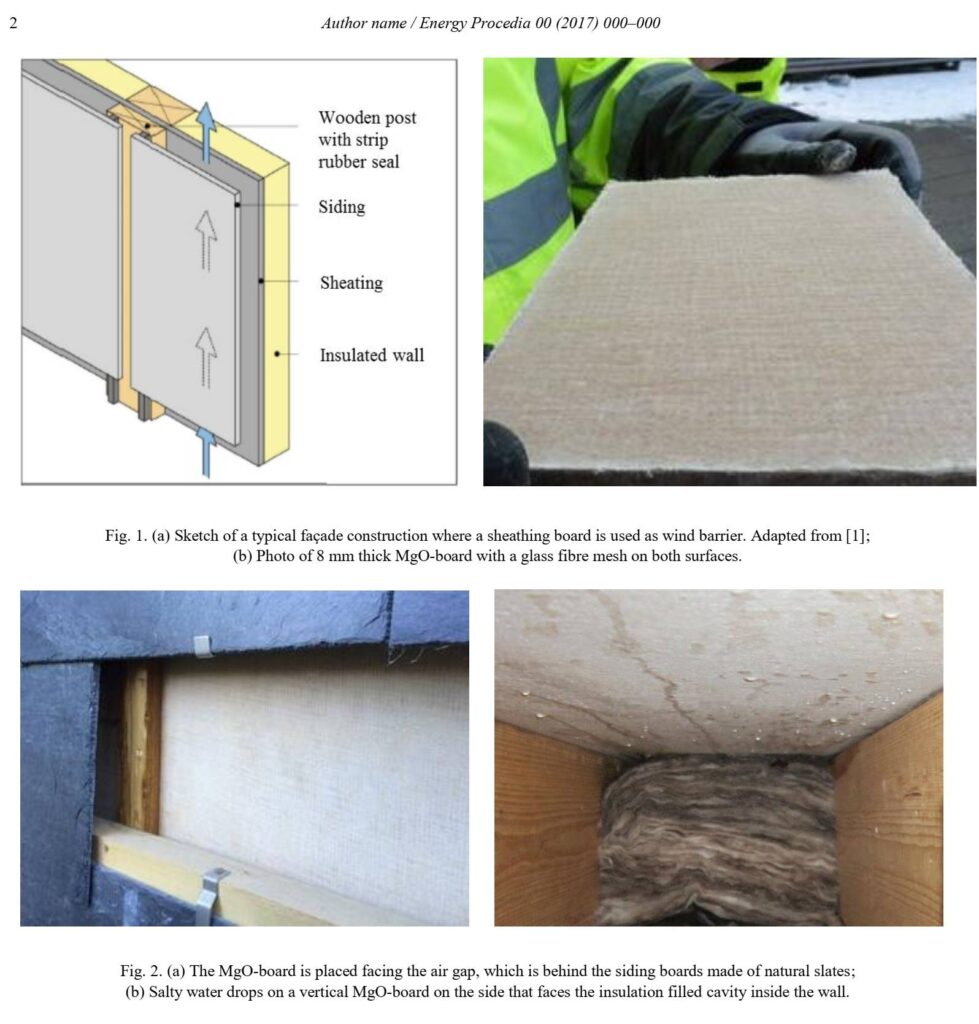

Magnesium oxide boards, commonly referred to as MgO boards, have gained popularity in the construction industry for their fire-resistant properties, lightweight design, and ease of installation. These factory-made sheathing products, often reinforced with glass fiber mesh, are typically composed of magnesium oxide (MgO) and magnesium chloride (MgCl₂), forming a binder known as magnesium oxychloride cement or Sorel cement. While they have been used in general building applications, such as interior walls or facades, recent evidence from research and guidelines highlights significant drawbacks that make them unsuitable for tunnel environments. Drawing from studies on moisture-related damages in buildings and specific recommendations for road tunnel fire protection, this article explores the reasons why MgO boards should be avoided in tunnels.

This article has been prepared as a caution for tunnel engineers and operators who consider using this type of products in their structures. The information contained here is based on the opinions from the professional communities and documents cited below.

If you still want to consider using MgO fire boards for tunnels, just do a simple test – get a sample of uncoated / untreated version of the product and put in a water container. See yourself how long it will last.

MgO boards – Moisture Absorption and Corrosion Risks in Humid Environments

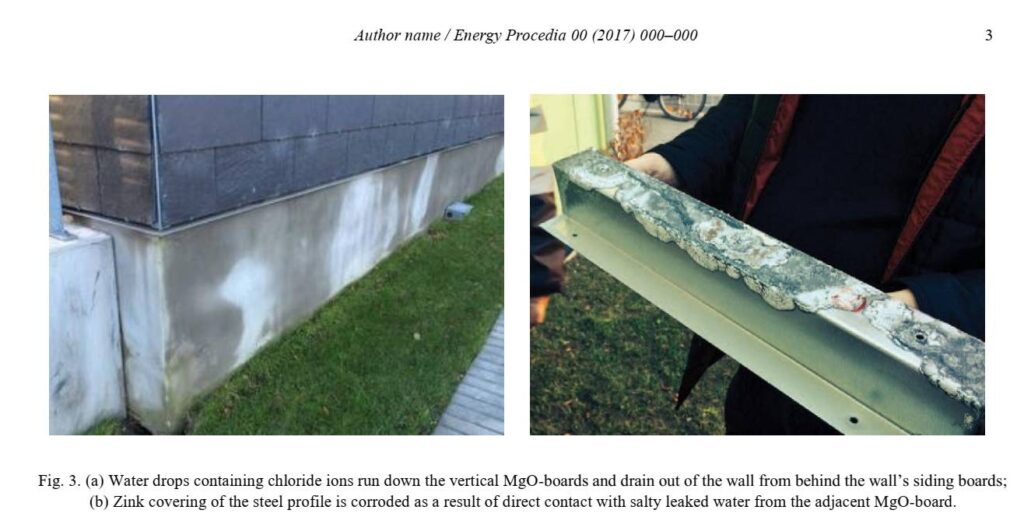

One of the primary concerns with magnesium oxide boards is their propensity to absorb moisture from the air, particularly in high-humidity conditions. A study conducted by researchers at the Technical University of Denmark, published in the proceedings of the International RILEM Conference on Materials, Systems and Structures in Civil Engineering 2016, documented widespread moisture damage in new and renovated Danish buildings where MgO boards were used as sheathing in ventilated facades. In winter 2014/15, these boards began exhibiting signs of distress, including the formation of water drops on their surfaces—often described as “tears”—that contained high concentrations of soluble chloride ions.

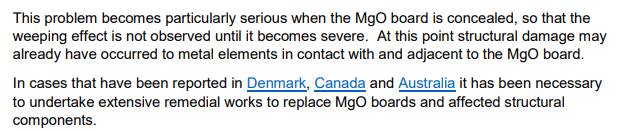

The mechanism behind this issue stems from the boards’ composition. MgO boards absorb ambient moisture when relative humidity (RH) levels reach 90-100%, leading to the leaching of chloride ions from the magnesium oxychloride binder. These salty droplets not only run down the boards but also drip onto adjacent structures, causing corrosion of metal fittings, anchors, and other components. In the Danish cases, metal mountings corroded heavily within just a few years, and mould growth was observed on nearby elements like insulation and wooden structures. The study also included investigations into the boards’ moisture absorption and desorption properties, confirming that they release significant amounts of chloride-laden water, which exacerbates damage in enclosed or semi-enclosed spaces.

Tunnels, by nature, are prone to high humidity due to limited ventilation, groundwater seepage, and condensation. The Guidance Notes on Design of Road Tunnel Structures and Tunnel Buildings, issued by Hong Kong’s Highways Department in March 2023, emphasize the need for durable materials in such environments, noting that tunnel designs must account for long-term exposure to moisture. In a tunnel setting, the moisture absorption issues seen in building facades would be amplified. Chloride leaching from magnesium oxide boards could corrode critical steel reinforcements, jet fans, cable trays, and anchors, leading to premature structural failure and increased maintenance costs. Unlike open-air facades, tunnels are confined spaces where moisture buildup is harder to mitigate, potentially turning minor leaks into widespread degradation.

CWCT in the UK also issued several technical notes on the subject of magnesium oxide boards:

Fire Safety Concerns and Release of Toxic Gases

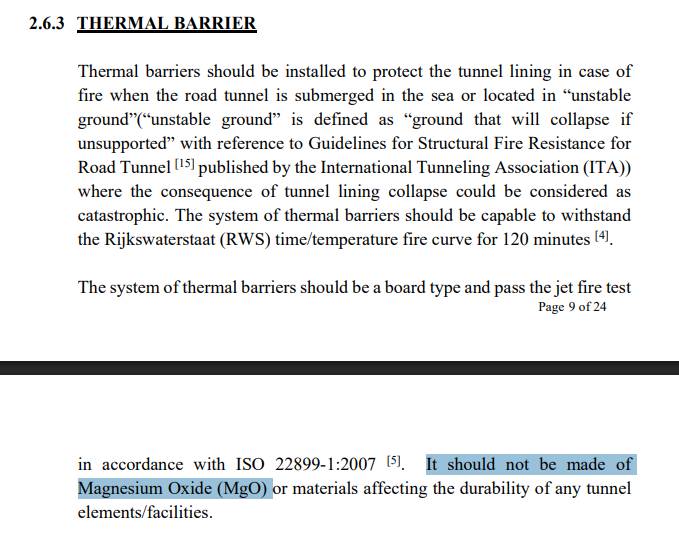

Beyond moisture issues, MgO boards pose serious risks in fire scenarios, which are a critical consideration for tunnels. The International Tunnelling and Underground Space Association (ITA) Working Group 6 on Maintenance and Repair, in their 2017 report on Structural Fire Protection for Road Tunnels, explicitly categorizes magnesium oxychloride-based materials as non-suitable for fire protection in tunnels. These boards, often marketed as “fiber-reinforced magnesium” or “magnesium oxide with silicates and additives,” contain chlorides that create technical and life-safety hazards.

During a fire, MgO boards can release hydrochloric acid (HCl) gas, a highly toxic and corrosive substance. This gas not only deteriorates the tenable environment inside the tunnel—making it dangerous for evacuees and rescuers—but also accelerates corrosion of surrounding metal components. The ITA report highlights that exposure to high temperatures causes the boards to break down, releasing HCl that could impair visibility, irritate respiratory systems, and hinder emergency operations. Independent research cited in the report, including studies from Australia, concludes that these materials compromise tunnel durability and safety, especially in high-humidity conditions where chloride leaching is already a problem.

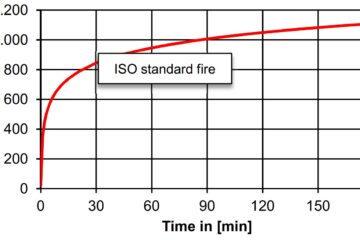

Tunnels are high-risk environments for fires due to vehicle traffic, fuel loads, and limited escape routes. The Hong Kong Guidance Notes stress the importance of fire resistance periods (FRPs) and thermal barriers that can withstand extreme events without compromising structural integrity. Magnesium oxide boards, while fire-resistant in controlled building settings, fail to meet these stringent requirements in tunnels. Their decomposition under intense heat could exacerbate fire spread, release dense smoke, and produce toxic fumes, violating life-safety standards outlined by organizations like PIARC (World Road Association) and ITA.

Maintenance and Durability Challenges in Tunnel Applications

Tunnel structures demand exceptional longevity, with design working lives often exceeding 100 years as per the Hong Kong Guidance Notes. Maintenance considerations are paramount, including provisions for inspection access, waterproofing, and resistance to environmental stressors. The Danish study revealed that MgO boards not only cause direct damage through moisture but also indirect issues like mould growth, which could proliferate in a tunnel’s damp, poorly lit interior.

In tunnels, where routine inspections are challenging and costly, the use of magnesium oxide boards would necessitate frequent interventions to address corrosion or water damage. The ITA report warns that chloride leaching negatively impacts long-term durability, potentially leading to expensive repairs or even tunnel closures. Organic matter sometimes found in these boards could further promote biological growth, compounding hygiene and structural problems.

The confined nature of tunnels amplifies these issues compared to buildings. For instance, in ventilated facades, excess moisture might evaporate or drain away, but in tunnels, it could pool, leading to persistent dampness and accelerated degradation. Guidelines from both the ITA and Hong Kong’s Highways Department advocate for materials like calcium silicate boards or vermiculite/cement sprays, which offer better resistance to humidity and fire without the chloride-related drawbacks.

Conclusion

While MgO boards may seem appealing for their cost-effectiveness and fire ratings in general construction, the evidence from real-world applications and expert guidelines clearly demonstrates their unsuitability for tunnels. Moisture absorption leading to chloride leaching, corrosion, and mould; the release of toxic HCl in fires; and long-term maintenance burdens make them a risky choice in these critical infrastructure projects. Tunnel designers and engineers should heed recommendations from bodies like the ITA and local authorities, opting instead for proven, chloride-free materials that ensure safety, durability, and operational reliability. By avoiding magnesium oxide boards, we can better protect lives and investments in underground transportation networks.

Sources:

Carsten Rodea*, Tommy Bunch-Nielsenb, Kurt Kielsgaard Hansena, Bent Grelk – Magnesium-oxide boards cause moisture damage inside facades in new Danish buildings

ITA – Structural Fire Protection in Tunnels – Working Group 6 – Maintenance and Repair

Guidance Notes on Design of Road Tunnel Structures and Tunnel Buildings to be maintained by HyD

Stefanie Wøhler Nielsen, Carsten Rode,*, Tommy Bunch-Nielsen, Kurt Kielsgaard Hansen, Wolfgang Kunther, and Bent Grelk – Properties of magnesium oxide boards used as sheathing in exterior walls

CWCT – Technical Note – The Use of MgO Boards in the Building Envelope

0 Comments